Designing of changed Weaves

- Satin and fabric weave

- Crepe weave

- Honey comb weave

- Mock leno weave

- Bedford Cords

- Satin may be a warp face rearrang twill and fabric may be a rearrange thread face twill. therefore textile is that the reverse facet of fabric weaves. These weaves type a very important class of weaves. they’re utilizein combination with alternative weaves, notably just in case of decorated materials. The placing feature of those weaves is their bright look and swish feel.

- The Basic characteristic of satin/Sateen Weave are:

- They are either warp or thread faced weaves.

- Have no distinguished weave structures.

- Only one binding purpose in every finish or choose

- No continuous twill lines

- Have poor seam strength thanks to thread quality

- More thread density is feasible in warp and thread

- More mass per unit space is feasible

- Have less binding points and additional float lengths

- Use of move numbers (intervals of selection) is critical to construct these weaves.In the construction of satin/sateen weaves, the handicraft points of warp or thread for a given repeat size is finished by the utilization of move numbers or sew or float numbers. The move numbers square measure elect in step with the repeat size of the weave.

- In selecting move numbers for the development of satin/sateen weaves, the subsequent rules square measure to be adopt:

- The move range shouldn’t be up to the repeat of the weave

- It shouldn’t be one but the repeat size

- It shouldn’t be an element of the repeat size, and

- It shouldn’t be a multiple of the issue .

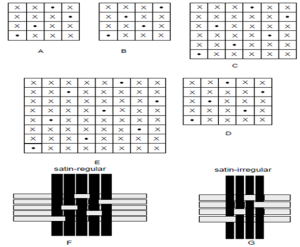

- The styles of some textile and fabric weaves square measure shown in

- Figs.A, B and C show the various sorts of irregular satins and Figs. D and E show the styles of standard textile. Fig. A shows a four finish irregular textile made by employing a step range of one, while Fig. B show identical textile made exploitation step range of two. Fig. D shows a five finish regular textile made with a step range of three and Fig. E shows AN eight finish regular textile made with a

step range of three. Fig. F and G shows the corresponding interlasings of styles D and A severally.

Satin-sateen checks

- Fig. shows a satin-sateen stripe style made on eight ends in an exceedingly repeat and Fig. shows a satin- fabric check style made on five ends in an exceedingly repeat.Creape Weave:Crepe weaves represent AN helpful style of straightforward weaves and are called “crape” or “oatmeal” materials thanks to their gravelly or rippled (rough) surface. the scale of the pebbles and their arrangement on material|the material} surface confirm the sort of crepe fabric.The crepe result are often achieved either by the utilization of crepe yarns (highly twisted) or a crepe weave, and generally by special method of finishing, i.e., embossing. Crepe weaves square measure normally utilized in combination with alternative elementary weaves, to provide a range of assorted effects in elaborate jacquard styles for brocade and connected materials.

- The Crepe weaves square measure characterised by the subsequent options :

- They contain no corded or alternative distinguished effects

- The cloth is roof by minute spots or seeds

- Highly irregular surface-puckered in look

- High twist yarns square measure used with controlled shrinkage

- Formed in the main by four ways, tho’ many ways square measure out there.Crepe weaves square measure made in an exceedingly style of forms supported the tip use necessities and therefore the sort of texture desired. they’re consequently made in lightweight, medium and significant constructions. usually the count of the warp yarns used is finer than the thread yarn. The weave used is of AN irregular nature. tho’ many ways square measure use within the construction of crepe weaves, four ways square measure primarily use,

- Construction of crepe weaves upon fabric base

- Combination of a floating weave with plain threads

- By reversing atiny low motif

Insertion of 1 weave over another.

Construction of Crepe weave upon fabric base:

In this case the bottom weave may be a fabric, upon that a select weave is insert to urge the irregular effects. this is often show in Fig.

At Fig. A, is show the bottom fabric weave and at Fig. B, is show the crepe result obtaine by insertion of a weave (3/1 and 1/3) upon the fabric base. The fabric weave has been mark with a unique notation so as to spot the bottom weave.

Combination of a floating weave with plain threads:

In this methodology a floating weave is insert upon an obvious weave to urge the required crepe result as shown in Fig.

At Fig. A, is show the insertion of taffeta weave. The arrow marks indicate the boxes wherever the floating weave is to be insert. The floating weave chosen here may be a combination of a four finish fabric and a twill (2/1 and 1/3). At C, is show the four finish irregular fabric, separately.

Small motif:

In this methodology a straight forward motif are o choO AND reverse at intervals inside the planning repeat to urge an irregular result as shown in Fig.

At A, is show a straightforward motif and at B, is show the crepe styles obtain by reversal of the motif at regular intervals.

Insertion of 1 weave over another:

In this methodology 2 completely different weaves square measure chosen and square measure inserted over each other to urge the required crepe result as shown within the Fig. 7.4. so as to provide AN irregular result, atleast one among the weaves ought to be irregular and would be higher if each square measure irregular. fabric and fabric derivatives square measure usually utilized in this methodology.In Fig. A, is show a fabric by-product and in Fig. B, is show a four finish fabric. In Fig. C, is show the crepe result obtaine by the insertion of A over B.- Typical Quality particulars for a crepe materialA typical kind of a cotton crepe material of fine quality and medium weight ought to have the subsequentspecifications :

- Warp – 18s

- Weft – 18s

- Warp threads/inch – fifty six

- Weft threads/inch – fifty six

- Warp yarn ought to have a bit a lot of twist than the thread

- .Uses of Crepe weave:Crepe weaves ar oftentimes used in conjunction with alternative elementary weaves, so as to provide a spread of various and different effects in elaborate jacquard styles for brocade and similar materials. {they ar|they’re} also used within the production of cotton product that are typically woven within the gray state, to be later on bleached and used for a spread of domestic functions. Crepe materials also are generally write with ornamental styles and sell as a light-weight and low cost material call “cretonne”, that is utilize extensively as loose coverings for article of furniture, antimacassars, covers, curtains and wall hangings, and for several alternative similar home articles

- Honey comb weave:The honey comb weaves derive their name from their partial similitude to the polygonal shape honey comb cells of wax during which bees store their honey. These weaves type ridges and hollows that provides a cell like look to the textures. each warp and thread threads float somewhat on either side, that as well as the rough structure, renders this category of material pronto absorbent of wetness. The weaves ar of 2 categories, namely,

- Ordinary honey comb or honey comb correct

- Brighton honey comb.Ordinary Honey comb weave:These weaves ar characterised by the subsequent options

- Cell like look with ridges and hollows.

- Single line crossing one line or double line crossing a double diagonal line.

- More warp and thread floats.

- Moisture absorbent because of floats.

- Constructed with pointed drafts.

- A reversible material having similar result on either side.

- Fig. A to F, show the look of a standard honey comb weave. Fig. A shows the primary step of constructing the look (single diagonal line). Fig. 5.1 B, C and D show the look, draft and peg arrange or standard honey comb weave created on equal ends and picks. A pointed draft is employ here. Fig. E shows the primary step within the construction of the honey comb weave on unequal ends and picks. Fig. F shows the ultimate style developed by incorporating a floating motif. Fig. 5.1 G shows the interlacement of style

- B.Brighton Honey Comb

- These weaves are characterise by the subsequent options :

- Non-reversible cloths during which face seems totally different from back aspect of the fabric

- Constructed on straight drafts solely

- Repeat size could be a multiple of four

- Length of longest float is N/2 – one, wherever N is that the repeat size

- A single diagonal line crosses a double diagonal line

- Formation of four cells per repeat i.e., 2 giant and 2 tiny cells (ordinary honey comb forms only 1 cell per repeat)

- The number of threads during a repeat should be a multiple of four.Fig. shows the development of a city honey comb weave.

- In the construction of city honey comb weaves, a diamond base is 1st create by insertion of one diagonal then a double diagonal to cross it. appropriate motifs as shown in figure on top of are insert within the areas of the diagonals. it’s to be remembere that the length of the longest float within the motif mustn’t exceed (N/2 – 1), wherever N is that the size of the repeat of the weave. Figs. B and C show

- brighten honeycomb styles created on repeat sizes of sixteen & twenty severally.

- Quality particulars of honey comb weave:The following artefact quality particulars are appropriate for each standard and city honey comb weaves,For a significant artefact,

- Warp – 2/6s cotton

- Weft – 2/6s cotton

- Ends/inch – fifty

- Picks/inch – twenty

- For a lighter artefact,

- Warp – 25s cotton

- Weft – 16s cotton mEnds/inch – eighty eight

- Picks/inch – eighty two

- Uses of honey comb weave:The materials created from honey comb weaves have a lot of thread floats on either side and have a rough structure. This renders a lot of absorption of wetness.The weaves are, therefore, appropriate for towels and conjointly in numerous forms for bed covers and quilts.

- Huck a Back weave:The towelling a back weaves ar essentially towelling materials. they’re usually relate to honey comb materials and therefore called honeycomb effects. they’re created by alternately combining a floating with an understandable weave. apparently, variety of weaves ar derived from these weaves.

- towelling a back weaves are appropriate for manufacturing thick and significant textures. one amongst the accept heavier types of this category is that the “Grecians”. the look of towelling a back weaves permits stripe and check effects to be come in the materials.

- The towelling a back weaves are usually characterise by the subsequent features:

- Repeat is split into four equal elements. 2 elements are full of taffeta weave and remaining 2 elements are full of long float motif.

- Plain weave provides firmness to the fabric.

- Long float motif provides wetness permeability.The loom instrumentality need would ideally be a dobby loom fit with a quick reed mechanism.

- The standard styles of towelling a back weaves square measure shown in Figs. 6.1 A and E. Fig. A show the planning of a “Devon” thuck a back on half dozen picks, that is employe for lower grade of cloths and figure E shows the planning of another sort of towelling a back appropriate for finer qualities of cloths. Figure H shows the interlacement of style

- Uses of towelling a back weave:Huck a back weaves square measure mostly use within the manufacture of each linen and cotton towels for bathtub rooms, and additionally linen towels to be used as glass cloths

- Mock lenos weave:Mock lenos, additionally called imitation lenos square measure a range of weaves of standard construction that turn out effects that square measure similar in look to the gauze or leno designs obtained with the help of doup mounting.

- These weaves square measure typically created together with a clear, twill, fabric or different straightforward weaves or maybe with brocade reckoning, to provide stripy materials, that bear a really shut likeness to true leno materials. 2 types of structures square measure created by the weaves,Perforated materials that imitate open gauze effectsDistorted thread effects that imitate spider or web leno designs.

- Perforated Fabrics:These square measure created by reversing atiny low unit of the weave. The weaves square measure in sections and have a tendency to oppose one another. The outer threads of adjacent sections tend to be force apart. the way of interweaving in every section permits the threads to without delay approach one another. Fig. 10.1 shows the varied styles of perforated material styles.

- The DISTORTED THREAD EFFECTS:

- The weaves of this class square measure thus organized to distort sure threads in either the filling or the warp, or in each filling and warp. The distorted thread effectsthe ground structure is apparent weave, and therefore the fourth and eleventh ends, that square measure distorted, float over all the plain picks, however pass underneath the fourth and eleventh picks. The latter float over one cluster of plain ends, and underneath consecutive cluster in alternate order. The distorted ends square measure placed on a separate beam and square measure given in additional apace than the bottom ends and thus they’re drawn towards one another wherever the picks four and eleven, float over the bottom ends. because the latter floats occur in alternate order, the ends square measure drawn along in pairs, and so separated, as indicated by the zigzag angular shape lines.

The distorted warp effects square measure primarily utilized in combination with different weaves in stripe kind. once utilized in stripe kind the ends that kind the zigzag angular shape result ought to be somewhat jammed within the reed

a distorted filling style. the planning is organized with plain ground similar. The floating ends hop over all the distorted picks, and alternately over the bottom picks between. so the distorted picks, that float over all the bottom ends, square measure alternately drawn along and separated, as shown by the zigzag angular shape lines

Uses of Mock leno weave

Mock lenos realize uses in canvas cloths, low cost materials for window curtains, lightweight dress materials, blouses, aprons etc. In several cases, they’re typically used together with different weave

Bedford Cords:

The bed ford cords square measure a category of weaves that turn out longitudinal warp lines within the textile with fine sunken lines in between. they’re created on a try of picks or alternate picks. The wire weave is alternated by weave filling manner. The wire effects thus created alter to bring out stripe effects in solid colors. typically cotton and worsted yarns square measure utilized in the assembly of bed ford cords.

- Cotton is used in weaving of lighter textures whereas worsted is employed in weaving of heavier textures. within the style of bed ford cords, 2 series of warp threads square measure thought-about. the primary cluster constitutes the face threads which weave as wire and weave on alternate or try of picks. the opposite cluster of threads renowned as cutting ends weave as plain. The cutting ends separate the neighbor cords. The cords could also be alternated by plain or weave filling manner.

Sometimes special threads called stuff threads square measure introduced in between the conventional warp threads. the aim of this can be to extend the prominence of the cords and additionally to extend the burden, bulk and strength of the material. The stuff threads ne’er interlace with filling, however lie utterly straight between the ridges of their various cords and therefore the floating filling at the rear. typically stuff threads are of significantly coarser counts of yarn than the principal or face warp threads, and since they never interlace with filling however stay straight, their construction throughout weaving is naught. This condition necessitates the stuff threads being wound upon a separate warp beam, and command at bigger tension than face warp threads throughout weaving.

Classification of Bed Ford Weave:

Standard Quality Particulars:

The following constructional particulars square measure appropriate for Bedford cords used as worsted dress materials.

- Warp : 2/20s

- Weft : 18s

- Ends/inch : ninety two

- Picks/inch : eighty twoThe following constructional particulars square measure appropriate for a cotton twill moon-faced Bedford cord (London cord).

- Warp : 14s

- Weft : 20s

- Ends/inch : eighty six

- Picks/inch : seventy eight

- Loom Equipment:A dobby loom with quick reed and serious beat up is appropriate for producing bed ford wire materials.

- Plain moon-faced Bed Ford Cords

- In this sort, the wire or rib result is create by alternating weave with the wire either on alternate picks or a try of picks. Fig. 8.1 shows the development of a clear face Bedford cord on a try of picks, and Fig. 8.2 shows a Bed Ford wire created on alternate picks.

repeat size of the cord. The repeat is split into cutting ends and face ends. The cutting ends weave plain and therefore the face ends weave the twine. In Fig. A the insertion of the cutting ends square measure shown within the figure B, the insertion of the face ends square measure shown. Figs. C, D, E and F show the planning, draft, peg arrange and therefore the cross section of the cord. At figure F, the interlacement of the varied picks within the repeat with the face and therefore the cutting ends square measure shown. within the example higher than the magnitude relation of face ends to cutting ends is 2 : 4.

the construction of an apparent moon-faced bed ford twine on alternate picks. Fig. A, shows the face and cutting threads. Fig. B, shows the insertion of weave on alternate picks to get the cord style.

Some wadded threads square measure introduced in between the face threads so as to extend the burden of the material or enhance the twine result. The wadded

Twill moon-faced Bed Ford Cord:

In this form of twine, a weave is employ rather than an apparent weave, in conjunction with the twine or rib weave to induce a stronger result. during this kind, the warp is conspicuously to the surface. Figure 8.4, shows the planning of a twill moon-faced bed ford twine.

The weave is insert on alternate picks. The repeat size of the twine is sixteen ¥ sixteen as well as the face and cutting ends. Wadding threads also can be introduced as within the case of plain moon-face Bedford cords.

A 2/1 twill has been chosen(figure B) and inserted with the twine. The stuff threads square measure inserted in between the face threads and work with the twine threads. The wadded threads don’t lay to rest weave with the picks.

Uses of Bed Ford Cords:

Bed ford cords realize a large vary of applications like dress materials, military dresses, suitings, woolen and worsted materials (heavy type).

RELATED LINK