Grinding machines are machines equip with grinding wheels use to perform grinding operations. Base on their function, they are generally divided into two categories. Conventional grinding machines are commonly use and are know as rough or snagging grinders. The following types of grinders fall under this category.

Grinders are tools use to grind workpieces, producing a smooth finish on flat surfaces. Grinding machines use grinding wheels coated with abrasive material to perform cutting. Each grain of abrasive material removes a small piece of the workpiece through shear deformation.

There square measure differing types of grinding machines looking on the needs. Types of Grinding Machines:- Following square measure the kinds of grinding machines:

- Bench grinding machine

- Hand grinding machine

- Pedestal grinding machine

- Portable grinding machine

- Flexible grinding machine

- Precision grinding machine

- Cylindrical grinder

- Plunge cut grinder

- Form grinder

- Internal grinder

- Centreless grinder

- Surface grinder

- Universal grinder

- Tools and cutting

- Base.

- Table.

- Column.

- Abrasive Wheel.

- Wheel Guard.

- Abrasive Wheel Head.

- Three varieties of Traversing Wheels.

- Coolant provide Nozzle.

Grinding Machine Components and Their Functions

Abrasive Wheel

The abrasive wheel has a coated surface that removes material efficiently from the workpiece during grinding.

Wheel Guard

The wheel guard covers the abrasive or grinding wheel to protect the operator from potential accidents during operation.

Abrasive Wheel Head

The wheel head holds the abrasive wheel and moves vertically using the vertical feed handwheel. You push the wheel head forward to bring the abrasive wheel into contact with the workpiece.

Types of Traversing Wheels

-

Hand Traversing Wheel

This wheel moves the table horizontally to align the workpiece with the abrasive wheel. -

Cross-Side Handwheel

This wheel moves the work table forward and backward, allowing controlled contact between the abrasive wheel and the workpiece. -

Vertical Feed Handwheel

This wheel moves the wheel head up and down to adjust vertical positioning and ensure precise grinding contact.

Fluid Supply Nozzle

The fluid supply nozzle directs coolant to the grinding zone. It prevents heat buildup in the workpiece and protects both the abrasive wheel and the material from thermal damage.

2.Hand Grinder3. Pedestal GrinderThis grinder is additionally mounted on the worktable or table. there’s a provision of moving the grinding wheels with tier.

Portable Grinder

You can easily carry a portable grinder anywhere. It allows grinding by hand and is commonly used to clean heavy welding jobs.

Manufacturers fit an abrasive wheel on one end of the motor shaft and install a handle or switch on the other end for operation. Use this tool carefully, as there is a risk of electric shock if mishandled.

Flexible Grinder

This type of grinder, shown in the figure, features an electric motor mounted on a base that allows movement in any direction. A flexible shaft connects to the motor shaft via a coupling. An abrasive wheel and handle are mounted at the end of the shaft. You can grind large jobs easily with this grinder.

Precision Grinder

This grinder includes a movable spindle mounted on a table along with its motor. You can rotate the abrasive wheel forward, backward, left, or right during operation. It delivers excellent surface finish and high accuracy, making it ideal for precision grinding tasks.

Types of Grinders

1. Cylindrical Grinders

This machine grinds cylindrical surfaces, and it can also handle tapered and simple contoured surfaces. You can classify cylindrical grinders based on how they support the workpiece.

-

Between centers: The workpiece is supported between two centers.

-

Centerless: The workpiece is supported by a work rest, a regulating wheel, and the grinding wheel.

Both types use plain grinding wheels where the outer diameter serves as the grinding face.

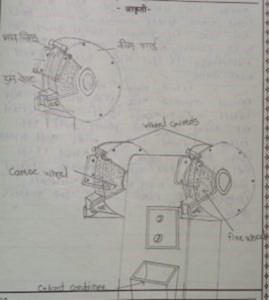

2. Centerless Grinders

Centerless grinders support and feed the workpiece using two wheels and a work rest. The larger wheel serves as the grinding wheel, while the smaller one acts as the regulating wheel. The regulating wheel, made of rubber-bonded abrasive, controls the rotational speed of the workpiece through friction.

You can adjust the wheel speed, typically ranging from 50 to 200 ft/min (0.25–1.02 m/s), to suit various materials and finishes.

Related link DRILLING MACHINE WORKING AND TYPES Measuring Tool-Vernier Caliper,Micrometer,Vernier Bevel RELATED MCQ TOOLS visit link face book whats up Instragram