To study the different phases of weft insertion in air jet loom

“This paper examines the fundamental phases of loom operation—shedding, picking, and beat-up—highlighting their role in fabric formation, loom motion types, and advancements in weaving technology for improved efficiency and automation.”

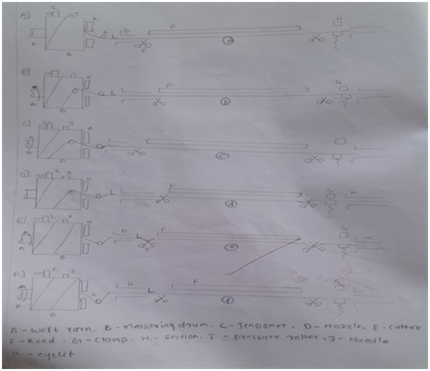

NAME: To study the different phases of weft insertion in air jet loom

THEORY: Weft yarn A is measured by a drum B equivalent to the width of cloth. Straightener also known as tensioned C loosens the weft yarn prior to welt insertion. After picking, the slack yarm is drawn back, and nozzle D spouts the weft yarn by compressed ait.

Suction tube H which is placed on the offside of the loom guides the inserted weft and inhales the well end which is cut by cutter.

a. The well yam is positively drawn out from a cheese/cone by measuring drum B and pressure roller 1 and winds itself round the measuring drum which continuously rotates three times for every cycle of weft insertion.

After the insertion of weft, needle I of the drum catches the weft yarn. The figure shows the weft yarn spouted the longest distance, about 20cm longer than width of the cloth. The air jet must be kept spouting from the nozzle up to this movement.

c. When the well yarn starts to wind itself around the drum, thread straightener C starts to swing forward and catches the weft yarn which lies between the eyelet K and the weft sensor E then return forward. The purpose of this motion is to draw back the weft yarn which has been spouted beyond the cloth edge as mentioned above, to open the limit switch of the weft sensor. Reed F is about to start moving forward.

d. Measuring drum is still at rotating and winds the weft continuously. The straightener draws ba the weft yarn to the cloth edge. This process is known as retraction of The reed continues to move forward. Air jet has been stopped spading reed continues its movement and holds the weft yarn between clamp Gon the temple and bar N gunted on the right end of the reed, thus completing the beating motion. At the time of beating, the cutters E on both sides cut the weft yarn so that its ends project about 6mm beyond the edge of cloth. Leno selvedge is formed at both ends During beating up, weft breakage may occur because of too high a tension. In order to avoid this thread straightener must be brought back slightly to loosen the yarn

1. The weft yarn which has been cut by the cutter hangs down at the nozzle. The straightener forward and draws back the weft yam to the nozaile tip. In order to keep the weft yarm in the to its inertia, the sorgle 51512210es correct position when the yarn is cut and weft tension is decreased due begim to spout air just before the yarn is to be cut. When the thread straightener reaches the lowest point, the weft and is drawn back To the nozzle. At this time the reed continues to swing back and is about 18mm distance to the back centre

CONCLUSION:- this way we studied different Phases of weft insertion in an jet loom.