Classification Of Textile Fibre

“Textile fibre serves as the primary raw material in textiles.Manufacturers twist fibres into yarns, which are then woven into fabrics. Subsequently, these fabrics are used to create clothing items. For instance, during the winter season, woolen clothing provides greater comfort; however, cotton is the best choice for summer. Therefore, having a basic knowledge of fibres and their classification becomes essential.

The fibres used in modern textile manufacture can be classified into two main groups –

– Natural and

– Man-made

Natural Fibre

“Natural fibres, such as cotton, wool, jute, silk, and flax, are provided by nature in a ready-made fibrous form. In contrast, man-made fibres are those that humans have developed by transforming substances that were not originally in a fibrous state into usable fibres.”

“Natural fibres can be subdivided into three main classes based on the nature of their source.”

– Vegetable

– Animal and

– Mineral

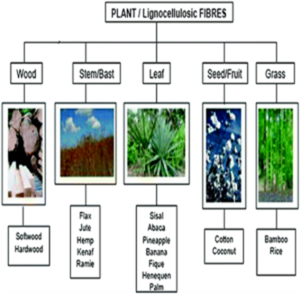

Vegetable Fibres

“These include the most important of all textile fibres – cotton, along with flax, hemp, jute, and others that plants produce.”

They are based on cellulose, the material used by nature as a structural material in the plant world.

Animal Fibres

These include wool and other hair-like fibres, such as silk, produced as filaments by cocoon-spinning creatures. “These animal fibres originate from proteins, the complex substances that form much of the animal body.”

Mineral Fibres

These are of limited importance in the textile trade.”Asbestos is the most useful fibre in this class; manufacturers use it to produce special fire-proof and industrial fabrics.”

Man-Made Fibre

We can sub-divide man-made fibres into two distinct classes based on the source of the fibre-forming substance used to make them.”

– Natural polymer and

– Synthetic

Natural Polymer Fibres

Nature creates natural polymers, including fibre-forming substances like cellulose. Plants produce vast quantities of cellulose, but only a small portion forms fine structures such as cotton. Most cellulose serves as a structural material, reinforcing tree trunks and the skeletons of stems and leaves. Although this cellulose appears fibrous, its contamination with other substances makes it unsuitable as a direct source of textile fibres.”

In the last half-century or so, we have learned how to manipulate this natural cellulose into a form suitable for use as textile fibres. It is the source that became known as artificial silks.

In these natural polymer fibres nature has done the work of creating a substance (cellulose) capable of taking on a fibrous form. Man has merely taken a further step by using this cellulose as raw material for a fibre.

In a similar way, it has been possible to use materials made by animals as a source of man-made fibres. The proteins used for so many structural purposes in the animal world are often capable of forming these. Nature has produced the proteins without necessarily using them for fibres. Man has then taken these proteins and manipulated them into a fibrous form. So we have natural polymer-fibres made from the proteins of peanuts and milk, maize, and soya beans.

Synthetic Fibres

These are those in which man has performed the entire operation of fibre-production without allowing nature to manufacture the fibre-forming substance. “Man produces fibres like Nylon, Terylene, and Orlon from simple chemicals derived from coal or oil. These chemicals are transformed into materials that can form fibres, and manufacturers then convert these materials into fibrous form.” Man has carried out the entire operation. Nature has had no hand in the production at all. They are truly synthetic fibres.

Related MCQ