Modern high production carding machine

In modern high-performance cards, the doffer comb and sloughing comb alone are insufficient for effective web handling. “In conventional cards, the web freely spans 30–50 cm, which causes it to disintegrate at high delivery speeds of 200 to 300 meters per minute used in advanced machines.” Developments chute feed system:

A feed system that delivers well-opened fiber tufts directly to the cards—without compressing them into a lap—is becoming essential for high-performance carding. This system contributes to increased production by enabling a heavier, yet thoroughly opened, batt. It not only eliminates the need for manual labor to transport laps from the blowroom to the card but also prevents clean fiber waste during lap changes.

Two basic chute feed system need to b considered here

- One-Piece chute without an opening system

- Two-Piece chute with an opening system

The one-piece chute forms a column of material whose height varies over time, and the feed roller pushes this material forward. This form of chute is simple uncomplicated economical and need little maintenance.

The two piece in more complex and expensive, but delivery a more even batt. The upper half is reverse chamber that serves to receive the material from the blowroom and to separate the material deliver In the lower portion (B), after an opening stage at the opening roller (2)

The system maintains consistent material quality. Pressurized air or vibrating plates (C) lightly compress the material continuously and evenly, forming a uniform batt—an ideal feedstock for the card.

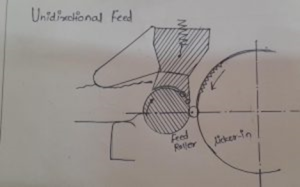

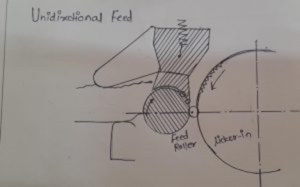

Unidirectional feed

In the new system shown in fig. the feed roller, situated below the feed plate, rotate in reverse direction which enables the feed to be led in the direction of rotation of the Taker- in which results in gentler treatment of fibers and therefore, leads to reduction in nep formation. “Operators adjust the clamping zone spacing when the feed and drum rotate in the same direction to ensure optimal material handling.”

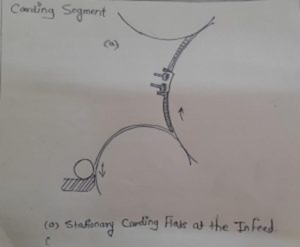

Use of carding segments:-

High performance cards require intensive opening, both in taker in and cylinder flat regions, to deal with higher through put. In the taker-in region, increasing the taker-in speed or the wire point density of its clothing can achieve this. However, increasing the taker-in speed proves effective only up to a certain point.”

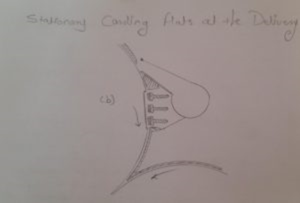

Use of carding segment around the cylinder:-

http://www.technicalshiksa.com

http://www.technicalshiksa.com

These carding segments function as full-fledged carding units, enabling fiber separation, trash separation with the help of a mote knife, and trash removal by suction.” One of the leading card manufacturer clamps that the knives are more effective in doffing of disc position.

“The most effective arrangement places the first carding segment around the cylinder just before the fibers enter the flats, and the second segment after the flats, above the doffer. These complete carding units effectively increase the number of carding zones from one to (one + number of carding segments). “As a result, the system maintains adequate fiber individualization even at very high production rates.” Additionally, this setup leads to a reduction in neps and improved removal of short fibers and trash.”

The use of carding segment on the front side(above the doffer) helps in removal of smallest trash and dust particles still remaining in the fibre mass. In the final analysis. therefore one can say that the use of carding segment reduce the loading of the a carding cylinder and flats and thus bring the

following advantages:-

1. Improve dust and dirt elimination.

2. Improved untangling of neps.

3. Increase in production.

4. Longer life of card clothing.

5. Possibility of usan he so finer clothing

6. Better yarn quality

7. Less damages to the card clothing.

http://www.technicalshiksa.com

http://www.technicalshiksa.com

Apron doffing:-

In modern high-performance cards, the doffer comb and sloughing comb alone are insufficient for effective web handling. “In conventional cards, the web freely spans a distance of 30–50 cm, which causes it to disintegrate at the high delivery speeds of 200 to 300 meters per minute used in advanced machines. “Therefore, it is advantageous to design doffing devices that not only guide the web effectively but also allow for easy extraction of the web for inspection—particularly for monitoring nep levels.”

Higher cylinder speed:-

“The cylinder diameter used in most modern cards is approximately 1300 mm, with operating speeds ranging from 250 to 600 rpm. In the quest for higher production, cylinder speed plays a central role. “Operators increase the cylinder speed accordingly to maintain an adequate number of wire points per fiber at higher throughput.” This ensures proper fiber individualization. Conversely, even at a constant production rate, increasing the cylinder speed improves fiber individualization, which in turn enhances yarn quality. Higher cylinder speeds are particularly effective in untangling neps. As a result, cylinder speeds typically range from 400–500 rpm for ring yarns and exceed 600 rpm for rotor yarns.”

High performance card wire:-

The first development which made a dramatic change in card productivity was the introduction of a metallic wire in 1965. This not only increase the productivity but also reduced card waste and eliminated frequent card stoppages to strip the cylinder and the doffer the further improvements in the design of the card wire such as optimizing wire bight, wire angle and wire point density lead to further increase in productivity and improvement in yarn quality is especially in reduction of nep level…

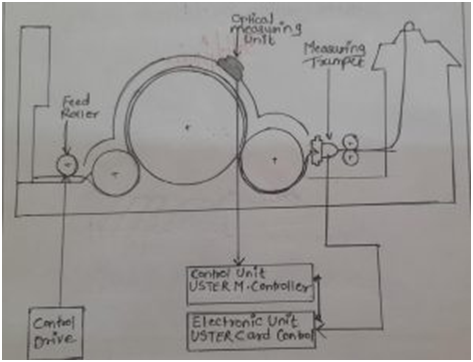

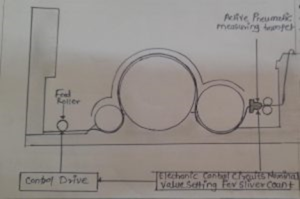

Online monitoring neps:-

The neps are a serious blemish in the yarn and need continuous checking. Now some manufacturers have come out with in built device to display the nep count of the card web. Therefore, immediate action can be taken to prevent excessive neps from passing into the card sliver ultimately into the yarn. Looking at the advantages of the devices it is accepted it might became a standard features of card in future.

Auto-leveling at card:-

“Therefore, operators can take immediate action to prevent excessive neps from passing into the card sliver and ultimately into the yarn. Given the advantages of these devices, many in the industry expect them to become a standard feature on future cards.”

Integrated grinding system :-

“The earlier discussion mentioned the on-line monitoring of neps in the card web.” To go further one can think of not allowing such a thing to happen by keeping the carding clements well ground. This has lead to development of the so called integrated grinding system, incorporated in the Rieter C-50 card automatically grinds the cylinder to maintain optimum sharpness of wire over its entire lifespan. All this takes place when the card is nunning and that too without operator intervention. An associated software determines the need for grinding and o actuates the grinding process.

Conclusion:

Thus we have studied various development in the carding machine.

visit link