Protective textiles fibers

Protective textiles

Protective textiles or protective clothing are an important branch of technical textiles that are used primarily for their functional or functional properties rather than decorative or aesthetic properties. The importance of protective clothing in the workplace is immense

Characteristics of Protective Textiles:

Protective textiles have several important features that should be present in every garment based on the workplace.

- Light weight and good Handle and Drape features

- High durability

- Water and wind resistant

- Resistant to bacteria and microorganisms

- Thermal insulation

- Ultraviolet (UV) resistant

- Air permeability

- Resistant to fire and flame

- Bulletproof

- Resistant to chemicals

- Provide protection from radar spectrum.

Raw Materials Used in Protective Textiles

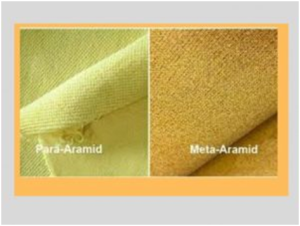

- Meta-Aramid Fiber:

Meta-Aramid fiber is used to make industrial protective clothing, racing driver’s suit, filter bag for hot gas, cargo cover, boat cover, fire hose etc.

- Pera-Aramid Fiber:Used to make tire cords, radiator hose, racing car brake shoes, strong combinations for aircraft, high-speed boat components, etc.

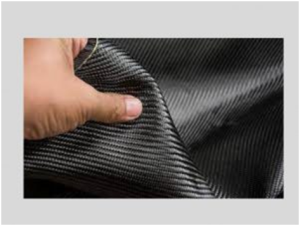

- Carbon Fiber

Carbon fiber is used in the manufacture of aircraft and space shuttles, industrial textiles, medical implants and marine textiles.

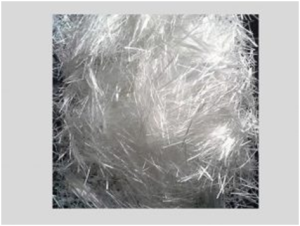

- Glass Fiber:

It is used in consumer products, corrosion resistant materials used in road covering, materials used in aircraft and aerospace systems etc.

- Polypropylene Fiber:

Polypropylene is also called PP. This fiber is used to make marine ropes and cables, boat sail protective clothing, boat or ship structure etc.

- Spandex Fiber:

Spandex is one kind of synthetic fiber which is used in clothing, hose, sportswear etc. Due to its elasticity, it is used to make many stretchable clothing.

- PBI:

Polybenzimidazole fiber is a one kind of synthetic fiber. It is used in making hot gas filtration, thermal protective clothing, racing driver’s suit etc.

- Tencel Fiber:

Tencel is made from plant materials like bamboo, cotton etc. Tencel fiber is used in the oil industry for filtration, medical textiles and industrial fabrics.

- Inorganic Fiber:

Inorganic fibers are made from inorganic materials. Glass fiber, alumina fiber, carbon fiber is called inorganic fiber, which is used in aircraft, automobiles, sports, electrical and military applications.

- Fluorine Containing Fiber:

It is used for corrosive filtration media, refrigeration and packing materials.

Classification and Application of Protective Textiles

Mechanical Protective Textiles

Mechanical performance of fibers, in their interlacing mode, hybrid yarns reach the textile material. This includes Ballistic, Blade cuts, Puncture, Projection of Fragments, Knives, Slashing etc. Acts as a personal defense against various risks such as

Flame Retardant Textiles

These types of garments are made using cotton/nylon as well as special fibers (carbon, glass, aramid, PBI) and chemical finishes, which reduce the combustion rate of the fabric. Workers in industries such as metals, aluminum and steel are often exposed to heavy molten metal splashes and work at very high temperatures

Chemical Protective Textiles

Activated Carbon used to be used in this type of clothing but now three layers of clothing are used, the outer layer protects from liquid chemicals, the middle layer absorbs liquid and gaseous chemicals and the inner layer provides comfort to the wearer.

Biological Protective Textiles

Microorganisms are microscopic organisms that include all unicellular organisms and can form an endosymbiotic relationship with the organism. This is why microorganisms act as effective agents in many infectious diseases

High Temperature Protective Textiles

This type of textile product is also used at a temperature of about 200 degrees Celsius, leaving the properties unchanged.

Radiation Protective Textiles

Protective clothing is used to prevent the body from being exposed to radioactive substances in a radioactive environment. These are commonly used for professional staff at cancer treatment centers, nuclear plants.

Ultraviolet Protective Textiles

The main role of UV protective clothing is to protect the skin against the harmful effects of the sun. Nowadays skin cancer is one of the most common cancers in the world, so changing the surface of textiles against UV radiation has become important especially for children’s clothing, sportswear, workswear.

Various Applications of protecting Textiles

Industrial Gloves:-

Industrial Gloves

Industrial hand gloves function Associate in Nursing item of protecting textiles or attire for staff in factories. they’re classified beneath Cut-Slash Protection moreover as Thermal Protection.

Gloves are best for cover from rough objects, sparks, and heat, and for padding from blows in heavy-duty work needs. Hand gloves ar of assorted varieties (leather, knitted, nitrile) and sizes (varying gauges).

The materials that get into the assembly of hand gloves vary from cotton materials and amphibole to a range of leathers, p-aramid, etc. Gloves ar wide utilized in business and Defence (Cut-Slash protection).

Due to fast manufacture, the employment of commercial hand gloves is anticipated to grow significantly. The gloves used for industrial and general functions ar classes as animal skin gloves, unwoven gloves, Non-latex gloves e.g. nitril gloves, Rubber/Latex gloves.

The animal skin, unwoven and nitril gloves ar utilized in industrial applications for cover and have consequently been mentioned during this section. The rubber/latex gloves ar used for surgical functions.

The typical characteristics of gloves ar delicate heat resistance, High abrasion protection, higher grip with anti-slip coating, snug and sturdy, Protection against cut and hot splash, for gloves made of Aramid (para) –temperature tolerance ranges from 250 to 750 Centigrade, nitril gloves offer chemical splash protection.

Other than animal skin gloves the unreal fibers used for industrial gloves embody Kevlar (Para-aramid), Spectra, Basophil, and Dyneema.

High Altitude Clothing:-

High altitude clothing:-

High altitude vesture is employed for cover against extreme climate like very vasoconstrictive, fast winds, snowfall, etc. particularly in important combat areas like Siachen.

The high altitude vesture consists of a jacket, waistcoat, trousers, ice mass cap, rappelling gloves, and ice mass gloves. The gear usually weight of special vesture is around 9 to 10 kilograms.

The typical characteristics of high altitude vesture are hydrophilic – Waterproof and wet resistant, Breathable, Abrasion resistance, Maintain high integrity, Resistance to fast wear and tear.

The material used for these vesture may be a usually hydrophilic polymer coating, Gore-Tex coating, or Sympatex coating. The hydrophilic properties are introduced by these coatings or laminates.

Microporous coatings or laminates may be made by mechanical fibrillation, part separation, solvent extraction, or solvent exchange.

Chemical protecting vesture (CPC):-

Chemical protecting vesture (CPC):-

Chemical protecting vesture (CPC) is employed for cover from chemical and physical hazards. The chemicals get absorbed into the figure in 2 ways that.

Physical contact- The chemicals get absorbed through the skin, Inhalation the chemicals within the aerosolised state get absorbed into the body through respiration.

Chemical protecting vesture is employed for the protection of the entire body against nephrotoxic chemicals that manifest their result by absorption through the skin. The sturdy Chemical protecting vesture is created of non-permeable textile materials (PVC/Rubber coated fabrics).

The protection is achieved by interference the penetration and permeation of the chemicals through the materials within the vesture. this is often an efficient methodology for providing decent protection to professionals from contact with nephrotoxic chemicals.

High Visibility Clothes:-

High visibility clothes:-

High visibility garments (also called Reflective-wear) became terribly essential for the protection of individuals operating in poorly lit environments like mines, highways, landing field runways, cyclists, etc.

In the dark, the high visibility vesture will increase the flexibility to identify operating and guiding personnel. There are broadly speaking 3 forms of high visibility vesture Reflection materials that shine once stricken by light-weight, Photoluminescent material which provides stoplight in dark, Fluorescent material that is a lot of visible even throughout the day Photoluminescent materials absorb the unreal light-weight and emit green-yellow light-weight within the darkness.

The major marketplace for these product is primarily the military and to a lesser extent NBC Emergency response units (National Disaster Management Authority)/Central Paramilitary Units/Other Civil Defense units etc.

Nuclear Biological and Chemical (NBC) Suits/Hazmat Suits:-

Nuclear Biological and Chemical (NBC) suits/Hazmat suits:-

Hazardous material (Hazmat) suits were designed to shield users handling venturous stuff like chemicals, material, etc. A a lot of specialized type of these suits ar NBC (Nuclear Biological and Chemical) suits.

Developed to shield troopers, these are designed to shield the user in a very hostile atmosphere with chemical/biological agents and against hot fallout mud.

The suits are designed to be worn for extended periods whereas continued to control in a very combat atmosphere. The NBC suit consists of a garment and jacket and may be used directly over the undergarments.

The suit is pervious and permits evaporation of sweat (breathable). The suit is created of 3 layers;

Inner layer: material cotton

Middle layer: Active charcoal treated non-woven.

Outer layer: material with chemical and fireplace agent fibers (inherently retardant).

The physical characteristics of the NBC suit ar Fire/Heat/Cold/Water repellent outer material, Breathable, Effective within the temperature vary of -35°C to +55°C, Resistance to wear and tear – high abrasion resistance, may be decontaminated a minimum of twofold, Washable, the period of time of 5 to seven years.

Fire/Flame agent attire (Protective Textiles):-

Fire/Flame agent attire (protective textiles):-

The fireplace/flame agent apparels have Associate in Nursing industrial would like as they provide protection from fire and different heat-intensive tasks. Flame, heat, and splashes of liquid metal, etc. are hazards in several significant engineering operating conditions.

The fire agent attire is employed in refineries, iron and steel plants, Al plants, and attachment industries. the fireplace agent attire may be factory-made from 2 types of material: 100% cotton material with flame agent coating or fabric made from inherently flame agent fiber.

The typical characteristics of the attire ar Flame resistance – should not conflagrate, ought to be breathable, simple to wear, light-weight ought to have high abrasion resistance.

RELATED LINK

for more details visit our

website link

Facebook Page link

Instagram page link

Gmail-link

Protective textiles or protective clothing are an important branch of technical textiles that are used primarily for their functional or functional properties rather than decorative or aesthetic properties. The importance of protective clothing in the workplace is immense