RELATION BETWEEN CRIMP AND FIBERS

“This paper investigates the relationship between fiber crimp and textile performance, focusing on how crimp affects fiber cohesion, bulk, strength, elasticity, and overall fabric quality in both natural and synthetic fibers.”

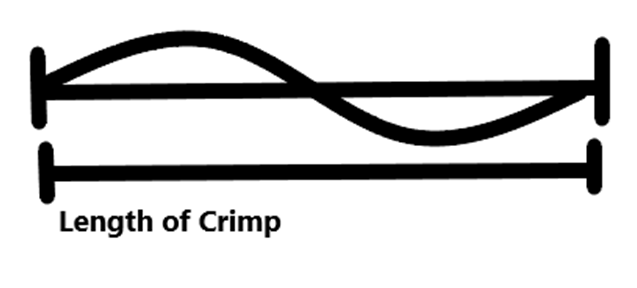

“Crimp means waves or Bumps of fiber.”

1.Fiber crimp properties occurs naturally in wool.

2.Can be added to manufactured fiber to emulate a natural fiber.

3.Added during the textile ring phase.

4.The waviness of fiber, that is the condition in which the axis of fiber under minimum external stress depart from the a straight line and follows a simple or complex or an irregular wave path.

5.Typically if the individual fiber of wool are fine the crimp will be fine.

6.If the crimp is fine, there are more crimp per length of fiber than the crimp was heavier.

7.The finer the wool the smaller the crimp spacing.

Formulae: Fiber crimp properties

| Crimp %= Extended length-original length/original length*100 |

Low crimp properties

1.lowe the percentage of short fiber.

2.Neep formation will be less.

3.Produce more clean wool.

4.clean yield is higher.

5.Higher yarn extension and elastic manual.

6.Produce softer and smoother knitted fabric.

7.Easier to process.

8.spun finer yarn with lower end break and low wastage.

9.Wool generally demonstrated better handle characteristics.

10.light weight clothing.

11.Produce stronger and summer garment.

12. Suitable for Women’s garment.

High Crimp Properties

1.Suitable for men’s winter clothing.

2.Result in better yarn Process.

3.High yarn shrinkage.

4.Can be used in heavier winter garment.

Finer crimp facts:

1.Cotton fiber crimp helps in spinning.

2.In wool garment, the crimp in the fiber makes them stands apart from each other.

3.As a result, little pockets of still air are trapped between the fibers.

4.This lining of air trapped inside the fabric acts as an insulator.

5.Low crimp are Straight than crimpy fibers the reflect light more effectively like tiny mirrors.

6.Hence the wool appearance relatively shiny and luster.

7.Depending on texture and Fineness of the fiber, From 60-80 % of the volume of the woolen fabric may be air.

8.Fine wool often, has 15 or more crimp per inch, coarser wool has less.

9.The wool from the back usually more crimp than wiil from front.

10.The critical structure of wool is related to the crimp in fibers.

11.wool fiber with little crimp do not blind as well as fiber with crimp ,therefore it is difficult to spin.

12.Fiber crimp is important in particularly in looser more in knitted produce where it has a significant influence on determined movement and the yarn fabrics is determine final of fiber weight ,shrinkage and pilling behavior of knitwear.

13.In higher twisted, tight set produce in woven fiber crimp, plays a lesser role.

14.Higher crimp fiber tends to move more during finishing operation this fiber properly contributes to the fabric dimensional stability and final fabric geometry.

15.Crimp can be artificially introduced the wool fiber during processing to enhance bulk.

16.The crimp increase the elasticity and elongation property of fiber.

17.Crimp% decrease when wet and increase when dry.

18.The relstion ship between the crimp and diameter was fairly poor.

19.More crimp means more finer yarn.

20.Higher quality of fiber have more crimp than those of lesser quality.