study on-line monitoring system

Online Monitoring for Nep Count in Yarn Production

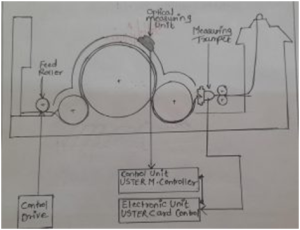

Neps, which are serious defects in yarn, require continuous checking in the spinning process. Traditionally, operators use tape to take off-bale samples of yarn from the card and manually check these samples for neps. However, some manufacturers have now introduced in-built devices that automatically display the nep count of the card web. This enables operators to take immediate action to prevent excessive neps from entering the sliver and eventually the yarn. With these advantages, manufacturers are likely to adopt this device as a standard feature on carding machines in the future.

Integrated Grinding System for Carding Elements

To further improve the quality of yarn, manufacturers have developed the Integrated Grinding System. This system, incorporated in the Riser C-50 card, automatically grinds the cylinders to maintain optimal sharpness of wire over its entire lifespan. Associated software determines the need for grinding and actuates the grinding process.

Keeping the carding elements well-ground prevents neps from forming in the first place.

The Integrated Grinding System is a cutting-edge technology that ensures the consistent production of high-quality yarn.

Conclusion:-

Thus, we have studied on-line Monitoring system.

visit link