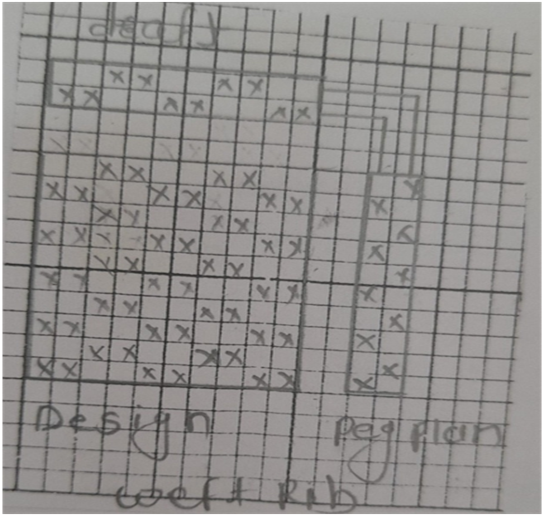

To analyze the given Weft Rib fabric sample.

“This paper presents a detailed analysis of a weft rib fabric sample, focusing on its structural characteristics, yarn arrangement, weave pattern, and fabric properties to understand its construction and functional performance.”

Apparatus : Beasley balance, crimp tester, fabric sample, picks glass etc.

THEORY:

Weft rib structure is the derivatives of plain weave. These are produced by entering the plain weave horizontally. In which two adjacent threads has interlacing with weft line in a one thread in the plain weave.

OBSERVATION TABLE:

| SR NO | EPI | PPI | WARP COUNT | WEFT COUNT | WARP CRIMP% | WEFT CRIMP % |

| 1 | 60 | 23 | 8.4394 | 9.52 | 15 | 8 |

| 2 | 59 | 22 | 8.50 | 9.52 | 13 | 9 |

| 3 | 60 | 23 | 8.30 | 9.49 | 16 | 8 |

| 4 | 58 | 23 | 8.43 | 9.52 | 14 | 10 |

| 5 | 59 | 24 | 8.43 | 9.53 | 16 | 7 |

| Mean | 60 | 23 | 8.43 | 9.52 | 14.8 | 8.4 |

Sample:

Calculation:

1.Warp count NE= 1.094*0.453/840*0.070

= 8.43 Ne

2.Weft count Ne=1.094*0.453/840*0.062

= 9.53Ne

3. Crimp %=Extended length-original length/original length*100

Warp crimp% =11.5-10/10 *100 =15%

Weft crimp%=10.8-10/10 *100 =8 %

4.GSM = (Weight of sample/25 *10,000

= 0.544/25 *10000

= 217.6 g/m²

5. Denting =EPI=60/2=30 = 30%

Result:

The following results are found from the above experiment.

EPI = 60

PPI = 23

Warp crimp% =148%

Weft crimp %= 8.4 1.

Warp count=8.4394 Ne

Weft count-=9.52 Ne

GSM=217.6

Denting – 2