To analyze the given Plain fabric sample.

“This paper provides a comprehensive analysis of a plain weave fabric sample, examining its construction, interlacement pattern, yarn arrangement, and physical properties to understand its role as a fundamental woven fabric.

NAME: To analyze the given Plain fabric sample.

To find weave, warp count, weft count, EPI, PPI.

Warp crimp & weft crimp% GSM, Denting

INSTRUMENTS: Beasley balance, crimp tester, fabric sample, picks glass etc.

Theory:

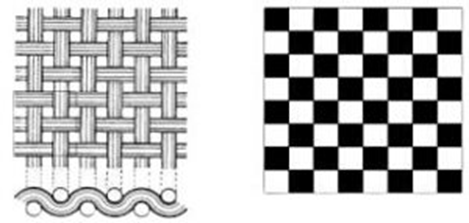

In plain weave the thread interlace in alternate order and weft thread are balanced that is similar in thickness and no, per unit area space two sense of threads bends about equality.

The weave is used for structure which range from very heavy and coarser blankets

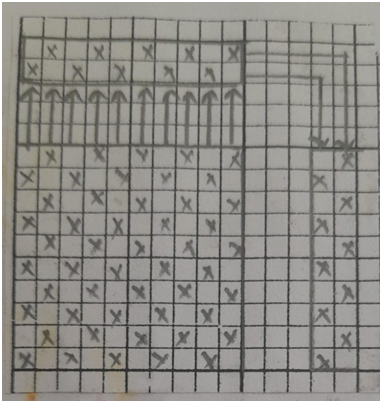

OBSERVATION TABLE:

| SR NO | EPI | PPI | WARP COUNT | WEFT COUNT | WARP CRIMP% | WEFT CRIMP % |

| 1 | 39 | 35 | 8.91 | 9.64 | 4.76 | 1.96 |

| 2 | 38 | 33 | 8.90 | 9.65 | 4.00 | 2.00 |

| 3 | 39 | 34 | 8.89 | 9.67 | 4.50 | 2.02 |

| 4 | 38 | 35 | 8.88 | 9.61 | 4.36 | 1.89 |

| 5 | 40 | 35 | 8.92 | 9.65 | 4.42 | 1.43 |

| Mean | 38.8 | 34.4 | 8.90 | 9.64 | 4.40 | 1.86 |

Calculation:

1.Warp count NE= 1.091*0.453/840*0.066

= 8.91 Ne

2.Weft count Ne=1.091*0.453/840*0.061

= 9.64 Ne

3. Crimp %=Extended length-original length/original length*100

Warp crimp% =10.5-10/10 *100 =4.76

Weft crimp%=10.2-10/10 *100 =1.96 %

4.GSM = (Weight of sample/25 *10,000

= 0.468/25 *10000

= 180 g/m²

5.Denting =EPI=39/2=19.5 = 20%

6.Reed Count=20/2 =10 Ne.

Result:

The Following Results are found from the above Experiment.

EPI =38.8=39

PPI=34.4 =35

Warp crimp%= 4.40%

GSM= 180 g/m²

Warp count = 8.90

Weft count = 9.64

Weft crimp%=1.86

Denting = 105 NE