What area unit medicine Textiles..???

Biomedical Textile

- ABSTRACT:

Fig1: FIBER OF medicine TEXTLEHISTORYAlthough textile materials are wide adopted in medical and surgical textiles for several years, new uses like medicine implantable materials area unit still being found.The first recorded use of fibres in drugs was mentioned in ‘Surgical Papyrus’ nearly four,000 years agone.within the ‘Susanta Sambita’ of the Indian Literature, written roughly two,500 years agone, a spread of materials area unit mentioned together with horse hair, animal skin strips, cotton, animal sinews and fibrous tree bark. As additional analysis has been completed, textiles have found their method into a spread of medical applications. additionally to protecting medical attire,textiles in fibre and material type area unit used as implants, filters and surgical dressings. Recent decades have witnessed major development in medical textile production, the materials they’re made from the and therefore the technology accustomed turn out them. medicine implants area unit accustomed aid or replace broken tissues or organs.</p>These materials area unit utilized in touching repair to the body whether or not it’s wound closure (sutures) or replacement surgery (vascular grafts, artificial ligaments,<p>etc.).&lt;/p>Although the natural thanks to replace a defective piece would be transplantation, this can be invariably unattainable thanks to several reasons. Therefore, physicians use a synthetic substitute (biomaterials) like biotextiles. the most attribute of a medicine textile is that it ought to fulfill the aim that it absolutely was designed. as an example, sutures could need a perishable textile. a synthetic ligament is permanent and is ready to react additional with blood cells and therefore the close tissues, compared to associate degree external bandage that is temporary and solely contacts the outer skin tissue.Material choice :</strong></p>Bio medical textile solutions utilize advanced compound, metal, and proprietary materials to make the building blocks for next-generation medical devices and instrumentation. unreal from a spread of permanent and absorbable fibers, BMS’ structures work aboard or as replacement for human structures within the orthopedical, vas, and muscular systems throughout the body.</p>Continuous medical textile engineering R&D is complemented by a verified record of anatomic pertinency experience. looking on the appliance performance necessities, BMS engineers select any combination of fiber variations, including:Monofilament. Single yarn, extruded; and measured by Mil or millimeter diameter.

Multifilament Yarn. Yarn consisting of the many strands which will be plied or twisted along, multifilamentmaterials have higher conformity, softer hand, and generally higher purpose than monofilament. Measured in Denier or Dtex.

Staple fiber. Short lengths of multifilament yarn used for non-wovens and alternative custom applications. Materials

Fig1: FIBER OF medicine TEXTLEHISTORYAlthough textile materials are wide adopted in medical and surgical textiles for several years, new uses like medicine implantable materials area unit still being found.The first recorded use of fibres in drugs was mentioned in ‘Surgical Papyrus’ nearly four,000 years agone.within the ‘Susanta Sambita’ of the Indian Literature, written roughly two,500 years agone, a spread of materials area unit mentioned together with horse hair, animal skin strips, cotton, animal sinews and fibrous tree bark. As additional analysis has been completed, textiles have found their method into a spread of medical applications. additionally to protecting medical attire,textiles in fibre and material type area unit used as implants, filters and surgical dressings. Recent decades have witnessed major development in medical textile production, the materials they’re made from the and therefore the technology accustomed turn out them. medicine implants area unit accustomed aid or replace broken tissues or organs.</p>These materials area unit utilized in touching repair to the body whether or not it’s wound closure (sutures) or replacement surgery (vascular grafts, artificial ligaments,<p>etc.).&lt;/p>Although the natural thanks to replace a defective piece would be transplantation, this can be invariably unattainable thanks to several reasons. Therefore, physicians use a synthetic substitute (biomaterials) like biotextiles. the most attribute of a medicine textile is that it ought to fulfill the aim that it absolutely was designed. as an example, sutures could need a perishable textile. a synthetic ligament is permanent and is ready to react additional with blood cells and therefore the close tissues, compared to associate degree external bandage that is temporary and solely contacts the outer skin tissue.Material choice :</strong></p>Bio medical textile solutions utilize advanced compound, metal, and proprietary materials to make the building blocks for next-generation medical devices and instrumentation. unreal from a spread of permanent and absorbable fibers, BMS’ structures work aboard or as replacement for human structures within the orthopedical, vas, and muscular systems throughout the body.</p>Continuous medical textile engineering R&D is complemented by a verified record of anatomic pertinency experience. looking on the appliance performance necessities, BMS engineers select any combination of fiber variations, including:Monofilament. Single yarn, extruded; and measured by Mil or millimeter diameter.

Multifilament Yarn. Yarn consisting of the many strands which will be plied or twisted along, multifilamentmaterials have higher conformity, softer hand, and generally higher purpose than monofilament. Measured in Denier or Dtex.

Staple fiber. Short lengths of multifilament yarn used for non-wovens and alternative custom applications. Materials- Polypropylene (PP)

- Polyester (PET)

- Polyethylene (UHMWPE – Dyneema Purity®)

- Nylon: polymer – Supramid™

- Polytetrafluoroethylene (PTFE)

- PEEK (Polyetheretherketone)

- PEKK (Polyetherketoneketone)</li>

- Silk

FIG: FIBRE SAMPLEMANUFACTURING METHODManufacturing of medicine Textile product may be a ton quite what goes in factories, textile mills.It includes:conceptualization, designing, choice of source, engineering, producing,distribution, promoting and marketing p

FIG: FIBRE SAMPLEMANUFACTURING METHODManufacturing of medicine Textile product may be a ton quite what goes in factories, textile mills.It includes:conceptualization, designing, choice of source, engineering, producing,distribution, promoting and marketing p - roduct.

(a) planning for producing is that the method of planning a product for low value, prime quality producing.(b) Engineering like package brings nice facilitate in optimizing the method.(c) Six letter quality: a method that uses information and applied mathematics ways to live and improve quality of a corporations operational

(a) planning for producing is that the method of planning a product for low value, prime quality producing.(b) Engineering like package brings nice facilitate in optimizing the method.(c) Six letter quality: a method that uses information and applied mathematics ways to live and improve quality of a corporations operational- performances by distinguishing and eliminating the causes of defects and minimizing variability in producing.(d) Maximize worth by eliminating wast(e) Life cycle analysis: a way to assess environmental impacts related to all stages of a product’s life from cradle to grave.

- Sutures </

</

- on the particular we

- b site.<

</

- for internal wound cl

- osures. Non-biodegradable sutures area unit wont to shut exposed wounds and area unit removed once the wound is sufficiently well.

lt=”” width=”300″ height=”291″ />

lt=”” width=”300″ height=”291″ />

- style=”font-size: 14pt;”><strong>Vascular graft implants Vascular grafts area unit used as a man-made vein or artery that’s established in heart to switch the first vein or artery that’s blocked or weakened. woof or wrap knitting technology is employed to form these grafts that area unit porous in nature that facilitate these grafts to amalgamate with new shaped tissues. so as to avoid hemorrhage once the implantation, the unwoven grafts with internal and external cloth is helpful, additionally they may be sealed with patients blood once the implantation is completed. Teflon is porous in nature and it’s best-known for its anti-clotting and bio-compatibility property.Soft tissue implantationSilk supermolecule, cellulose, chitin, chitosan and albuminoid area unit a number of the biological polymers that area unit compatible with the soft tissues. a number of the biological materials that area unit used for creating soft tissues area unit carbon fibre, synthetic rubber and polymer

- . Soft tissues created from synthetic rubber area unit utilized in artificial breasts, nose and ears.Hernia repairIn herniation repair additionally medical specialty textiles area unit used. Like as an example plastic mesh is employed for herniation repair. This mesh has resistance to infection and allergies.The fibres might be woven in line with the need of the patient.Hard tissue implantationNow-a-days medical science surgeons value more highly to use non-woven fibrous mat that is formed from plumbago and Teflon round the medical science implants to spice up up the tissue growth. These implants area unit applied to replacement of bones and joints and fixation plates that area unit used for helpful broken bones.Dental bioma</strong>terials</strong>Major needs of dental polymers embrace uncloudedness or transparency, stability, smart resilience and abrasion resistance, quality in oral fluids, non-toxicity, comparatively high softening purpose and straightforward fabrication and repair. the foremost wide used chemical compound for dental use is poly (methyl methacrylate) (PMMA) and its derivatives. alternative materials for dental plate base polymers area unit polysulfone and polyether polys ulfone.

FIG :SURGEONS WEARExternal devicesBandages, stritches etc

FIG :SURGEONS WEARExternal devicesBandages, stritches etc

FIG:BANDAGEImplantable materials ,Sutures, vascular grafts, artificial ligaments

FIG:BANDAGEImplantable materials ,Sutures, vascular grafts, artificial ligaments

FIG: SUTUREHygiene merchandisepads, nappies, tampons, healthful towels, etc

FIG: SUTUREHygiene merchandisepads, nappies, tampons, healthful towels, etc

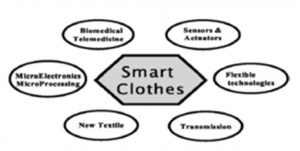

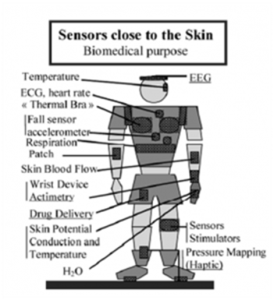

FIG: healthful TOWELEXAMPLE OF medical specialty TEXTILEBiomedical good Clothing: Smart vesture with sensors placed in shut proximity to the skin area unit used for medical specialty applications. The sensors area unit typically engulfed within the layers of cloth or on its surface. In some cases, the material itself is employed because the sensors. Piezo-resistive yarns, optic fibers, and coloured multilayer, all area unit used as sensors. The medical specialty good vesture has many advantages: it’s placed mechanically within the correct location (avoiding the need of inserting the sensors on the patient by a nurse or physician); it’s discreet, nonvisible, well protected, and user friendly.</p>it’s notably well custom-made for the watching of chronic diseases, of the disabled, and therefore the old. they’re additionally used throughout skilled activity.

FIG: healthful TOWELEXAMPLE OF medical specialty TEXTILEBiomedical good Clothing: Smart vesture with sensors placed in shut proximity to the skin area unit used for medical specialty applications. The sensors area unit typically engulfed within the layers of cloth or on its surface. In some cases, the material itself is employed because the sensors. Piezo-resistive yarns, optic fibers, and coloured multilayer, all area unit used as sensors. The medical specialty good vesture has many advantages: it’s placed mechanically within the correct location (avoiding the need of inserting the sensors on the patient by a nurse or physician); it’s discreet, nonvisible, well protected, and user friendly.</p>it’s notably well custom-made for the watching of chronic diseases, of the disabled, and therefore the old. they’re additionally used throughout skilled activity.

FIG;SMART garments

FIG;SMART garments

FIG: SENSORS getting ready to SKINUSES OF medical specialty TEXTILE

Why ought to we tend to use a medical specialty textile?</strong></p>There area unit several uses of medical specialty textile parts in device style. for instance they’re utilized in minimally invasive surgical devices thanks to their flexibility and near-net form similarly as their controlled body, density, absorbility, radial/tensile strength. medical specialty textile structures may be built to move inside the body to push h</p>ealing.</p>Another clear advantage is that the useful flexibility and strength that may facilitate maintain a patient’s vary of motion throughout and once surgery recovery. the benefits of medical specialty textiles area unit clear; they provide a minimally invasive delivery profile, versatile any medical device style. style choices,and a large number of physical and mechanical properties,

FIG: SENSORS getting ready to SKINUSES OF medical specialty TEXTILE

Why ought to we tend to use a medical specialty textile?</strong></p>There area unit several uses of medical specialty textile parts in device style. for instance they’re utilized in minimally invasive surgical devices thanks to their flexibility and near-net form similarly as their controlled body, density, absorbility, radial/tensile strength. medical specialty textile structures may be built to move inside the body to push h</p>ealing.</p>Another clear advantage is that the useful flexibility and strength that may facilitate maintain a patient’s vary of motion throughout and once surgery recovery. the benefits of medical specialty textiles area unit clear; they provide a minimally invasive delivery profile, versatile any medical device style. style choices,and a large number of physical and mechanical properties,

“228” />

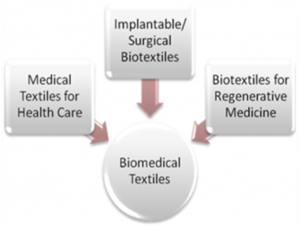

FIG:BIOMEDICAL T</p>EXTILES<strong>CONCLUSION</p>Biomedical science has become terribly advanced from previous few decades. a lot of and a lot of techniques area unit unreal to obtain higher health ways. but substitute for defective half|part|piece} was wont to be transplantation of that partor organ, however this can be not invariably doable. so use of biotextiles as a substitute to switch and aid for broken body components is being used by the surgeons and physicians</p>. one in every of the foremost vital side to contemplate is that the bio-compatibility of such textiles with the material body on that they’re used. therefore to guage their bio-compatibility testing is completed that determines however the material body can react to the particular medical specialty textile.</p>Today medical specialty textiles area unit a product of collaboration between medical researchers and textile human with scope and application.Biomedical textile area unit one in every of the dynamically increasing sector and development of same to conver painful days of patient into snug day .RELATED LINKSAFETY

“228” />

FIG:BIOMEDICAL T</p>EXTILES<strong>CONCLUSION</p>Biomedical science has become terribly advanced from previous few decades. a lot of and a lot of techniques area unit unreal to obtain higher health ways. but substitute for defective half|part|piece} was wont to be transplantation of that partor organ, however this can be not invariably doable. so use of biotextiles as a substitute to switch and aid for broken body components is being used by the surgeons and physicians</p>. one in every of the foremost vital side to contemplate is that the bio-compatibility of such textiles with the material body on that they’re used. therefore to guage their bio-compatibility testing is completed that determines however the material body can react to the particular medical specialty textile.</p>Today medical specialty textiles area unit a product of collaboration between medical researchers and textile human with scope and application.Biomedical textile area unit one in every of the dynamically increasing sector and development of same to conver painful days of patient into snug day .RELATED LINKSAFETY

FIG: FIBRE SAMPLEMANUFACTURING METHODManufacturing of medicine Textile product may be a ton quite what goes in factories, textile mills.It includes:conceptualization, designing, choice of source, engineering, producing,distribution, promoting and marketing p

FIG: FIBRE SAMPLEMANUFACTURING METHODManufacturing of medicine Textile product may be a ton quite what goes in factories, textile mills.It includes:conceptualization, designing, choice of source, engineering, producing,distribution, promoting and marketing p (a) planning for producing is that the method of planning a product for low value, prime quality producing.(b) Engineering like package brings nice facilitate in optimizing the method.(c) Six letter quality: a method that uses information and applied mathematics ways to live and improve quality of a corporations operational

(a) planning for producing is that the method of planning a product for low value, prime quality producing.(b) Engineering like package brings nice facilitate in optimizing the method.(c) Six letter quality: a method that uses information and applied mathematics ways to live and improve quality of a corporations operational